| Author |

Message |

| < 16ga. Ammunition & Reloading ~ Handy Trick for MEC Crimp Starter |

|

Posted:

Fri Jul 31, 2015 10:16 pm Posted:

Fri Jul 31, 2015 10:16 pm

|

|

|

Joined: 08 Feb 2009

Posts: 1310

Location: Western WA

|

|

I was having trouble with buckling and splitting near the crimp when reloading once-fired Cheddite hulls with my MEC 600 Jr. Then I noticed that the buckling and splitting appeared to start by one of the three long crimp fingers inside the plastic MEC crimp starter.

So I took my Dremel tool and removed about 2-3mm on each of the 3 long fingers, smoothly fairing them down to the inside of the crimp starter.

That did the trick. No more case buckling or splitting, perfect tight crimps each time.

Brewster |

|

|

|

|

|

|

|

Posted:

Sat Aug 01, 2015 8:22 am Posted:

Sat Aug 01, 2015 8:22 am

|

|

|

Member

Joined: 15 Apr 2007

Posts: 9464

Location: Amarillo, Texas

|

|

??

A picture would be most helpful

Thanks

Mike |

_________________

,

,

USAF RET 1971-95 |

|

|

|

|

|

|

Posted:

Sat Aug 01, 2015 8:49 am Posted:

Sat Aug 01, 2015 8:49 am

|

|

|

Joined: 16 Jul 2015

Posts: 2126

Location: Hudson,Wy

|

|

He is referring to the modern snap on style plastic crimp starter. If you take one of these "Spindex" starters in your hand and turn it over to look inside you will notice 3 alignment ribs that extend into the tapered section (4 on an 8 pt. starter). The idea is that these ribs naturally rotate the starter head into position as the press handle is pulled down. I can often see the head rotate into position. These are the ribs that were trimmed back. They would have been made shorter in length, leaving a gently tapered transition.

It looks like a 1/2" sanding drum would be the easiest means if trimming them back. The operation should only take a few seconds. The older (pre 83) all metal units didn't have the ribs and seemed to work well enough anyway. |

_________________

Only catch snowflakes on your tongue AFTER the birds fly south for the winter... |

|

|

|

|

|

|

Posted:

Sat Aug 01, 2015 9:19 am Posted:

Sat Aug 01, 2015 9:19 am

|

|

|

Member

Joined: 12 Mar 2005

Posts: 6535

Location: massachusetts

|

|

All my MEC 600 Jr. presses are older models with the original internal type stamped aluminum or brass crimp guides. Steel spacer discs placed on top of the crimp guide inside the die limit the guide's upward movement which determines the crimp height once the die is adjusted. The spacers are supposed to loosely hold the guide so it can spin and index itself the to existing hull crimp folds. The design leaves a lot to be desired, especially for 6 point crimps.

I add one or two thin card discs to limit the movement of the guide. I then orient the guide to a known position and simply index the hulls to the guide before I crimp. Problem solved.

All my Grabbers are fitted with the new snap on guides. As directed in the MEC owner's manual, I apply dab of light grease to the ball before snapping the crimp guides in place. The grease allows the 8 point Spindex crimping guides to work perfectly, but I occasionally still have problems with 6 point guides.

I finally put a witness mark on the outside of the 6 point crimping guide, and then align it and the hull crimps beforehand. Easy peasie solution to a PITA problem. Works for me. Might work for the newer MEC 600 Jrs. and Size Masters if the grease doesn't. |

|

|

|

|

|

|

|

Posted:

Sat Aug 01, 2015 11:11 am Posted:

Sat Aug 01, 2015 11:11 am

|

|

|

Joined: 16 Jul 2015

Posts: 2126

Location: Hudson,Wy

|

|

| The 600 I use for loading 10 Ga. still has the old metal starter. The shim adjustment was inadequate and I ended up using washers between the assembly and press frame. The newer style Spindex provides much better adjustability, but I never remember to get one for 10 ga. when I place a reloading order! |

_________________

Only catch snowflakes on your tongue AFTER the birds fly south for the winter... |

|

|

|

|

|

|

Posted:

Sun Aug 30, 2015 1:59 pm Posted:

Sun Aug 30, 2015 1:59 pm

|

|

|

Joined: 08 Feb 2009

Posts: 1310

Location: Western WA

|

|

Here are some pics (with apologies for large size):

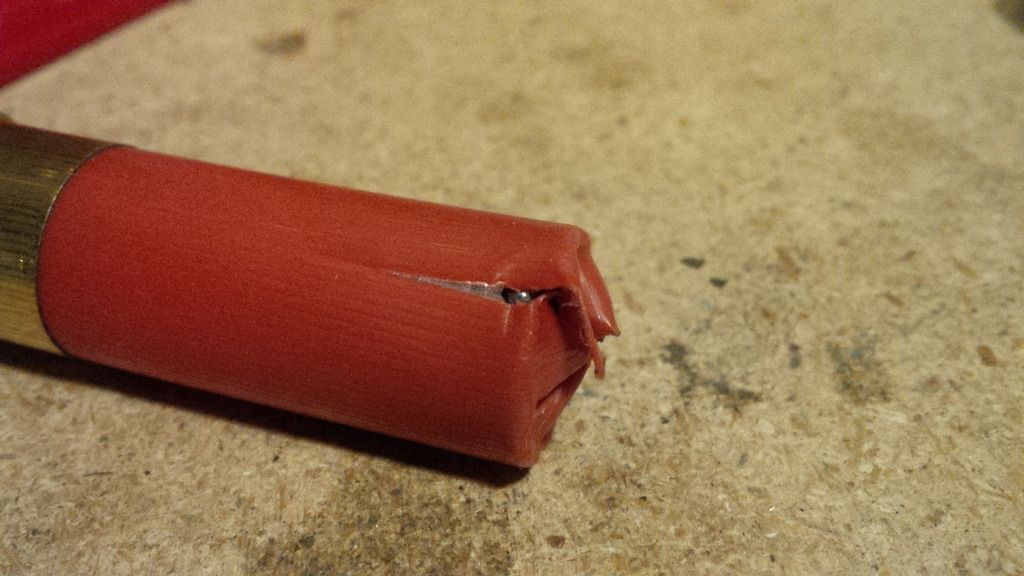

Problem: Once-fired 2 1/2 in. cheddite splitting and buckling after crimping:

Cause: Long rib in MEC crimp starter is gouging hull:

Solution: Grind down long ribs in MEC crimp starter with Dremel:

Outcome: Perfect crimp and reload!:

Thanks,

Brewster |

|

|

|

|

|

|

|

Posted:

Sun Aug 30, 2015 5:30 pm Posted:

Sun Aug 30, 2015 5:30 pm

|

|

|

Member

Joined: 15 Apr 2007

Posts: 9464

Location: Amarillo, Texas

|

|

Looks promising

Thank you for the pictures

Mike |

_________________

,

,

USAF RET 1971-95 |

|

|

|

|

|

|